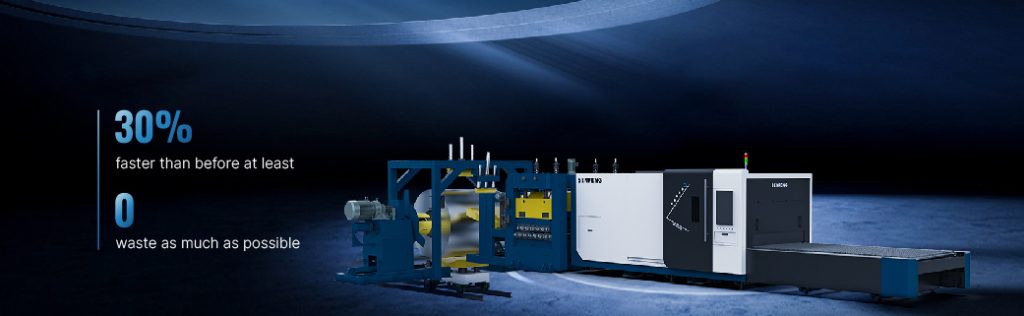

This blanking line adopts high power and large working area to cut thick and heavy sheet coils. Combining decoiling, leveling, feeding and cutting together, this machine has developed into a one-stop production line from mere cutting.

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

| Main Parameters | Model | |

| SF2012CH | ||

| Decoiling and Leveling Unit | Size of Sheet Coil (L*W, mm) | 4000*2000 |

| Thickness of Sheet Coil (mm) | 8-14 | |

| Standard inner diameter of sheet coil (mm) | Φ610/Φ762 | |

| Max outer diameter of sheet coil (mm) | Φ1000-1800 | |

| Weight of Sheet Coil (T) | 20 | |

| Max Feeding Speed (m/min) | 10 | |

| Leveling Accuracy (mm/m²) | ±5 | |

| Laser Cutting Machine | Laser Power (kW) | 6 |

| X/Y-axis Positioning Accuracy (mm/m) | ±0.05 | |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | |

This model, unlike other ordinary blanking lines only cutting thin sheet coils, can handle with 14mm thick sheet coil at most. With less working procedures, it is complementary to those models, so as to make our product line perfect

⇲ Special for large, thick and heavy sheet coils

* Max size of sheet coil: 4000*2000mm, inner diameter: Φ610/762mm, outer diameter: Φ1000-1800mm, thickness of sheet coil: 8-14mm, weight of sheet coil: 20T

* Its double-headed decoiler, hydraulic loading trolley, 11-roller leveling device and laser cutting machine with large working area work together to insure fast speed and high quality while cutting such special sheet coils

* Deal with carbon steel, AL alloy, brass, red copper, galvanized sheet, silicon steel sheet, electrolytic plate, titanium alloy, etc.

⇲ Cutting-edge processes

* Content-rich process package for lightning-fast cutting with mirror-like surface

* Utilize our patented rapid stress relief technology, which not only levels the sheet but also relieves internal stress, making the sheet flatter

* With ultra-high-precision positioning correction technology, its guide rollers are asked to correct sheets in real time, so as to avoid any offset and enable accurate positioning & high cutting precision

⇲ Need less costs of purchase

* Compared with punching and other traditional laser cutting modes, it can raise its material utilization by 5-10%

* We offer automatic auxiliary gas distribution device, so its control software may select gas type and pressure automatically to make manual operation unnecessary and save relevant costs

* With this machine, users prefer sheet coils to cut-to-length steel plates, enabling flexible clipping and much less costs of purchase because of their large price spread

⇲ Fully-enclosed structure

Laser cutting machine, with top cover, is designed as fully-enclosed to separate cutting area and prevent smoke dust from diffusion. Workers in the workshop will be in good health

⇲ Automatic assembly line

This assembly line is fully automatic, with no manual intervention from automatic loading, decoiling, leveling, feeding, cutting to unloading device. 30% faster than before at least and realize 0 waste as much as possible

⇲ International famous components

* Heavy-duty decoiling, feeding and leveling unit with steady structure and high carrying capacity

* New fiber laser generator outfitted with anti-reflectivity protection and high electro-optical conversion rate

* Fully-enclosed laser cutting head can prevent dust pollution effectively

* The cutting unit uses multiple sets of AC servo motors for faster response and more accurate control

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Protect both man and machine

* There are more than one set of safety monitoring systems. Its whole process is clear at a glance. If abnormal, alarm will be given in time to prevent unforeseen shutdown

* Adopt protective measures to avoid misoperation and users may cut off the power at full speed in case of emergency

* Electrical system has high capacity of resisting disturbance and automatic diagnosis to find the cause of failure quickly

Our self-developed intelligent system can correlate technical parameters to sheet coil (such as thickness) in its database, so that this production line may adapt to material change quickly and make its control fully digital and automatic.

⇲ Follow-up control

Adjust follow-up height from cutting head to sheet automatically to eliminate the impact on cutting effects of uneven sheets

⇲ Lightning-fast piercing

Pierce at top speed and enhance efficiency especially when cutting thin sheet

⇲ Recut from break point

Remember the cutting position after power outage, start recut from break point once power recover, thus avoiding material waste

⇲ Ink jetting system

Generate labels in batch and make inkjet printing more precise and eco-friendly

⇲ Safety grating

Protect both man and machine by warding off accidents

⇲ Self-developed nesting software

Nest and typeset in full volume to maximize material utilization

Fiber laser cutting machines work by directing a high-power laser beam onto a material’s surface, which heats and melts the material. The laser beam is guided by a fiber optic cable, allowing it to cut with precision and speed. The process involves localized heating, causing the material to melt or vaporize in the targeted area, and high-pressure gas is used to blow away the molten material, resulting in a clean cut.

Fiber laser cutting machines are highly versatile and can cut a wide range of materials, including:

⇲ Metals: Stainless steel, carbon steel, aluminum, copper, brass, and titanium.

The cutting thickness depends on the power of the laser. Generally:

⇲ For low-power machines (1kW-3kW), cutting thickness ranges from 1mm to 16mm for steel.

⇲ For high-power machines (above 3kW), cutting thickness can go up to 200mm for metals like steel, and thinner for reflective materials like aluminum or copper.

Yes, we provide comprehensive training and technical support to ensure that our customers are fully equipped to operate the machines. This includes installation guidance, operational training, and ongoing support.

If your machine experiences a malfunction, you should first contact our technical support team for assistance. We offer remote troubleshooting services and, if necessary, can send technicians for on-site repairs.

Yes, we offer regular maintenance services to ensure the longevity and optimal performance of your machine. Our maintenance packages can be customized based on your usage needs.

We offer a warranty that typically covers key components such as the laser source, control system, and motors. The warranty period is generally two years, depending on the product. Extended warranties and service packages are also available.

The price of a fiber laser cutter varies based on factors such as power, size, and additional features. Machines typically range from $30,000 to over $200,000 depending on the configuration.

We accept a variety of payment methods, including bank transfers (T/T), letters of credit (L/C), and other methods like leasing or financing options, depending on your location and specific needs.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.