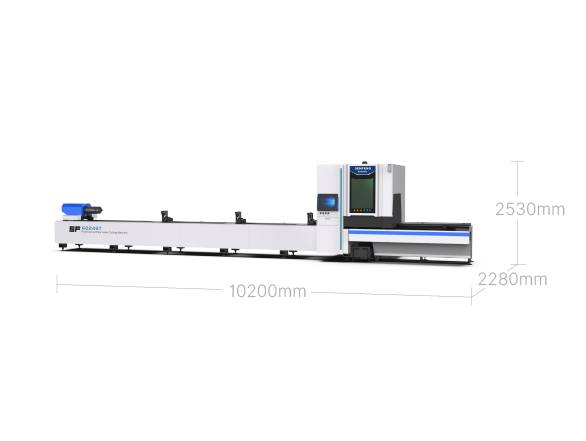

Bevel Tube Laser Cutting Machine

1.5-8

【KW】

Laser power6000

【mm】

Max length of tube350

【mm】

Max size of tube700

【kg】

Max weight of tube2

【year】

Warranty period

【KW】

Laser power【mm】

Max length of tube【mm】

Max size of tube【kg】

Max weight of tube【year】

Warranty period

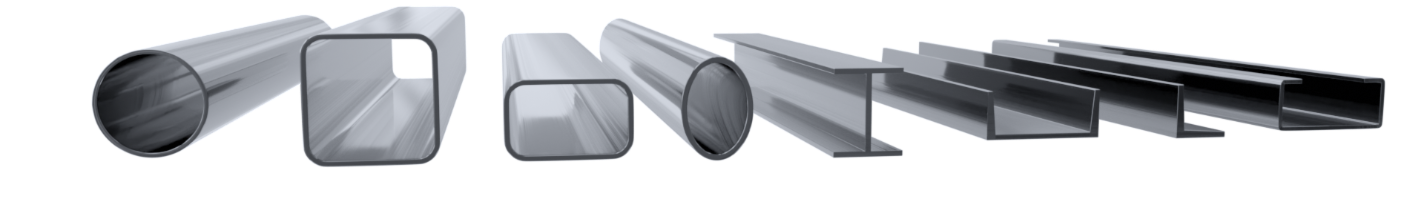

GT series can cut most of metal tubes available on market, including conventional and special-shaped tubes. In this way, users will break through tube limitation, expand work scope and sharpen their competitive edges.

Wood

Wood

Glass

Glass

Leather

Leather

Acrylic

Acrylic

Gold

Gold

Silver

Silver

Platinum

Platinum

Paper

Paper

MDF

MDF

Other non-metals

Other non-metals