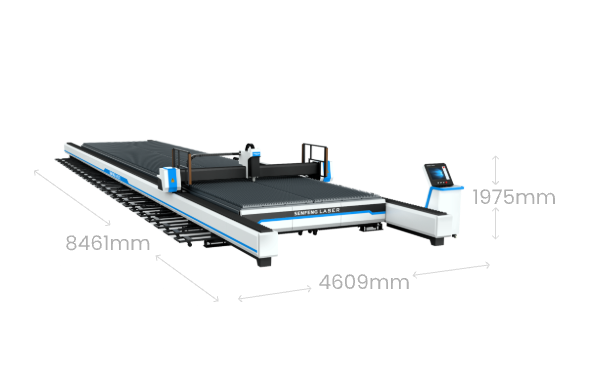

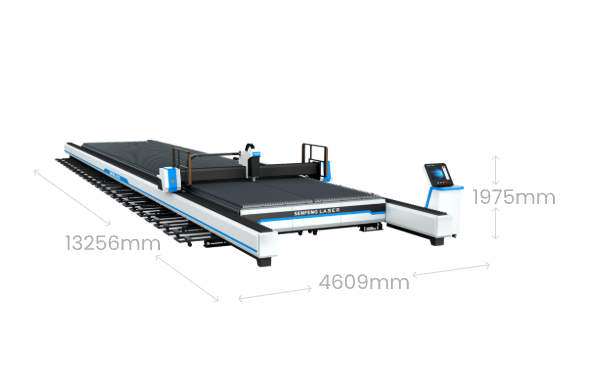

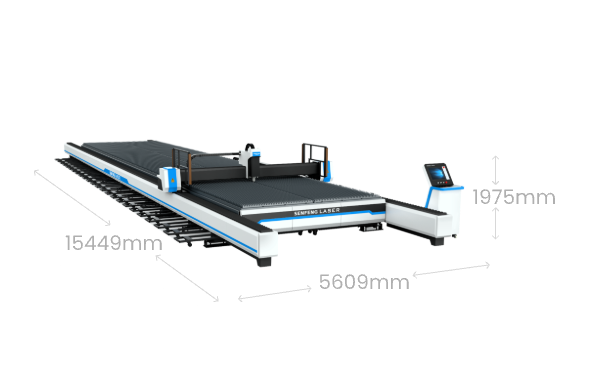

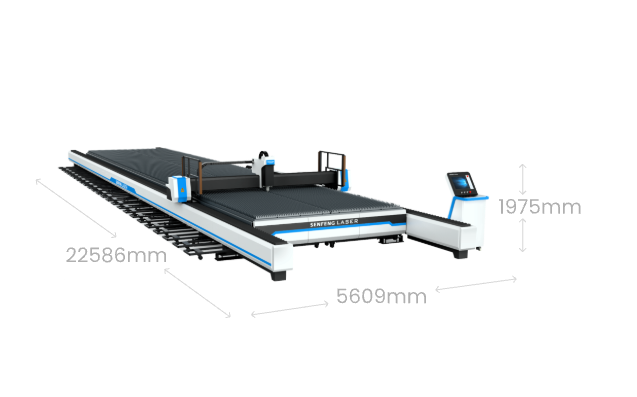

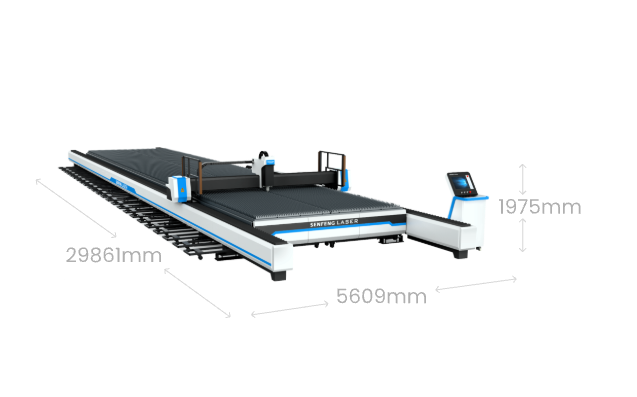

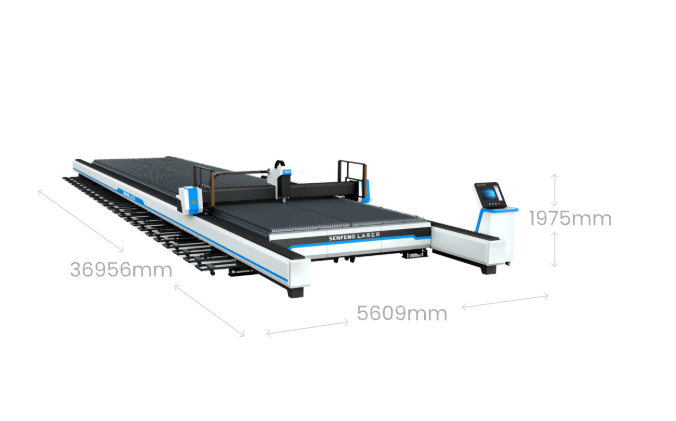

Ultra Large Metal Sheet Fiber Laser Cutter

6~60

【kW】

Laser power30000*4000

【mm】

Max working area100

【m/min】

Max no-load speed47

【T】

Max load of single platform2

【year】

Warranty period

【kW】

Laser power【mm】

Max working area【m/min】

Max no-load speed【T】

Max load of single platform【year】

Warranty period

This machine is mainly used for cutting extra-large and ultra-heavy sheets. It is ideally suitable for those heavy industries incl. iron tower, steel structure, engineering machinery, mine and shipbuilding.

Carbon steel

Carbon steel

Stainless steel

Stainless steel

AL alloy

AL alloy

Brass

Brass

Galvanized sheet

Galvanized sheet

Silicon steel sheet

Silicon steel sheet

Electrolytic sheet

Electrolytic sheet

Titanium alloy

Titanium alloy

Manganese alloy

Manganese alloy

Wood

Wood

Glass

Glass

Leather

Leather

Acrylic

Acrylic

Gold

Gold

Silver

Silver

Platinum

Platinum

Paper

Paper

MDF

MDF

Other non-metals

Other non-metals