⇲ Growing market size year by year

⇲ Increasing important innovation in technology

⇲ Diversified demands from customers

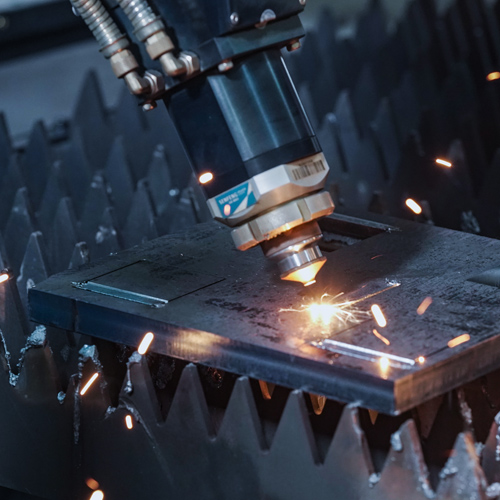

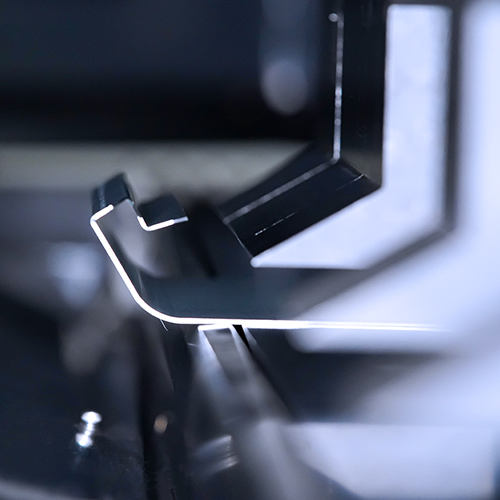

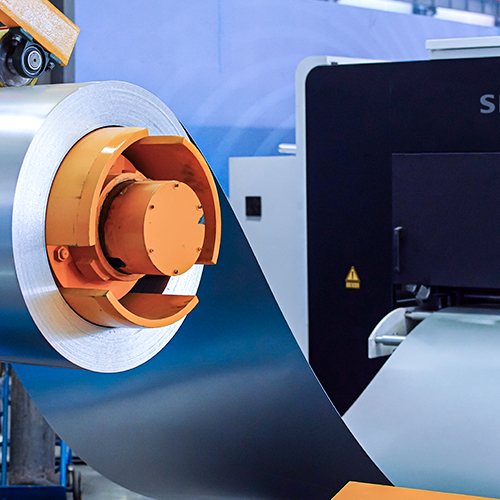

In spite of growing demands, the market competition is intensifying, which forces relevant companies to make a way to serve with products and services of higher quality at lower costs. Given this, some common crafts recommended to them include:

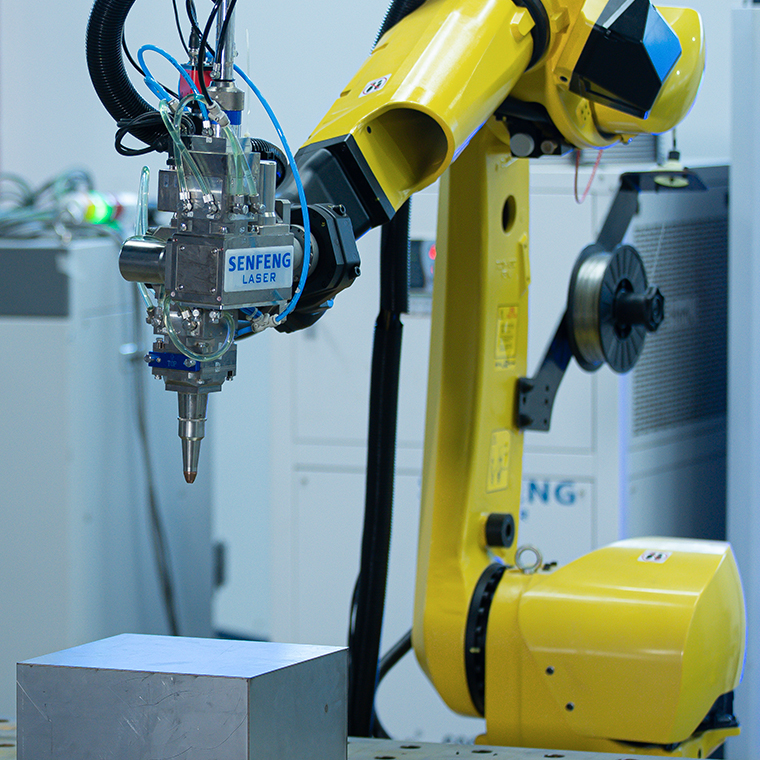

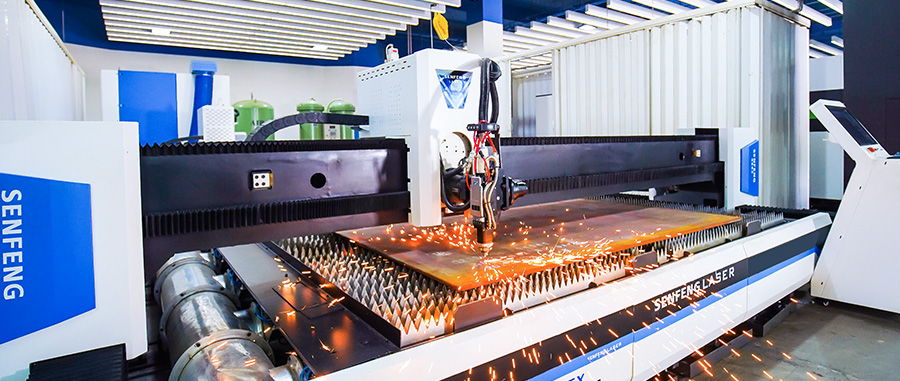

With full industry chain, SENFENG is able to provide one-stop solutions covering laser cutting, bending, welding and automatic production line. We want to deliver the higher labor efficiency, faster work speed, higher product quality and lower production costs to users.

HSD is a Chinese metalworking company that mainly cuts medium-thick plates. Previously, they relied on manual beveling, which involved many processes, high labor input but low efficiency. After using SENFENG's Ultra-large Beveling Laser Metal Cutter SF26040TX Series, it is 75% faster than before because of one-step forming of ±45° bevel. Besides, it is easy to cut plates in batch, making for a significant increase in order volume.

⇲ Time of purchase: Nov. 2023

⇲ Specific model: Ultra-large Beveling Laser Metal Cutter SF26040TX

Completely synergize resource taxing.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.