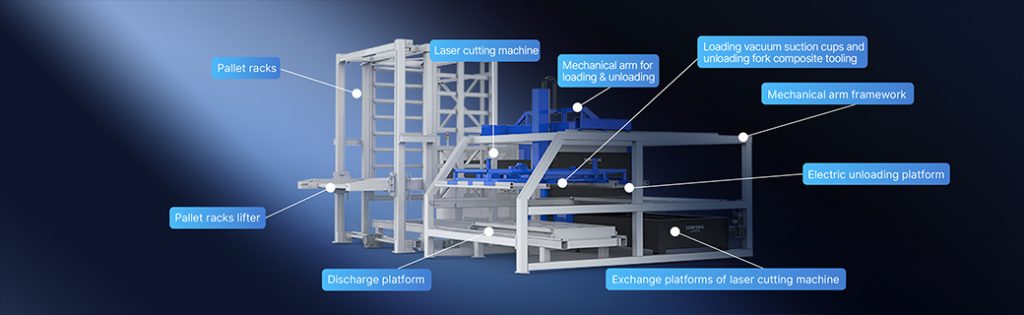

It consists of sheet pallet racks, automatic loading & unloading devices, CNC control systems and others, and works in conjunction with a laser cutting machine to form an automated sheet metal production line. It can enable automatic loading & unloading and stereo storage of sheets, providing users with well-arranged and compact sheet storage solutions.

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed

| Each Parts | Item | Technical Parameters |

| Storage Unit | Number of Layers of Pallet Racks | 8 |

| Layer-to-layer Height (mm) | 360 | |

| Stack-up Height of Each Layer (mm) | 280 (with wooden pallet) | |

| Carrying Capacity of Each Layer (kg) | 3000 | |

| Loading & Unloading Unit | Running Speed of Trolley (m/min) | 2-15 |

| Lifting/Translation Speed of Mechanical Arm (m/min) | 12/60 | |

| Warehouse-in/out Speed (m/min) | 10 | |

| Cutting Unit | Laser Power (kW) | 6 |

| Max Size of Sheet (mm) | 3000*1500 | |

| Min Size of Sheet (mm) | 800*800 | |

| Sheet Thickness (mm) | 0.8-12 | |

| X/Y-axis Positioning/Repositioning Accuracy (mm) | ±0.05/±0.02 | |

| Max No-load Speed (m/min) | 130 | |

| Max Load of Platforms (kg) | 2000 |

This production line achieves one-stop automatic operation from work scheduling, sheet storage, retrieval, loading, cutting, unloading to waste transfer, which can save occupied area and space for sheets, and serve users with convenient sheet storage and handling.

⇲ Stereo storage of sheets

This 8-layer pallet rack allows for stereo storage of sheets, fully utilizing vertical space of workshop to facilitate production

⇲ Automatic sheet detection

Laser loading & unloading system, through intelligent modules, can detect double layers of sheets, then, separate one from the other and pick up only one sheet at a time to prevent overload

⇲ Automatic warehouse-in/–out

Sheets, under PLC control, are usually fed to the grabbing position. Then, robotic trolley picks up and sends them to laser cutting machine

⇲ Make rational scheduling

It can arrange production automatically based on the predefined plans, so as to make unmanned work possible and minimize human error

⇲ Loading & unloading devices

* Vacuum suction cups used for loading. The unloading fork has smooth surface and minimal contact area with sheets to avoid them from scratch

* Loading & unloading robotic arm is made of high-strength steel pipes and quality steel plates, then, which will go through stress relief after overall welding, for high rigidity and precision

* Sheet handling trolley is driven by servo motor and speed reducer while lifting up/down and warehousing-in/out, in a word, it can move rapidly at high positioning accuracy

* Pallet rack lifter is also equipped with synchronized balance cylinder to keep itself more stable during quick lifting and avoid vibrations

⇲ Safety fence

Safety fence around the production line can prevent unauthorized access and avoid unexpected downtime

⇲ Heavy-duty thermal isolated hollow bed

* Laser cutting machine’s bed is fully hollow, with no internal connection. Such structure helps to cut off heat transfer and extend its lifespan

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Intelligent spiral negative-pressure dust removal

Laser cutting machine can open and close air outlets based on cutting position. Combined with bottom sealing structure, it can cut with smoke-free effects

The CNC system is outfitted with advanced program controller and touch screen, featuring perfect detection, fault self-diagnosis, interlocking, alarm and protection.

⇲ Visually displayed interface

Show the debugging, setting, manual operation and other functions on touch screen for simple operation

⇲ Demonstration memory programming

Switch between automatic and manual mode at will, adapting to different working states

⇲ Intelligent start and stop

No need for manual control, make process transition smoother, save energy and protect environment well

⇲ One-to-many operation

Its modular expansion allows users to freely combine according to their needs. A single loading & unloading system can serve multiple cutting machines at the same time, maximizing factory space

⇲ Personalized customization

The layer number of pallet racks can be tailored. We can provide individual solutions for users

⇲ MES integration

Reserve interfaces to dock with user’s MES system, as thus, prepare for the establishment of intelligent and digital workshops

Fiber laser cutting machines work by directing a high-power laser beam onto a material’s surface, which heats and melts the material. The laser beam is guided by a fiber optic cable, allowing it to cut with precision and speed. The process involves localized heating, causing the material to melt or vaporize in the targeted area, and high-pressure gas is used to blow away the molten material, resulting in a clean cut.

Fiber laser cutting machines are highly versatile and can cut a wide range of materials, including:

⇲ Metals: Stainless steel, carbon steel, aluminum, copper, brass, and titanium.

The cutting thickness depends on the power of the laser. Generally:

⇲ For low-power machines (1kW-3kW), cutting thickness ranges from 1mm to 16mm for steel.

⇲ For high-power machines (above 3kW), cutting thickness can go up to 200mm for metals like steel, and thinner for reflective materials like aluminum or copper.

Yes, we provide comprehensive training and technical support to ensure that our customers are fully equipped to operate the machines. This includes installation guidance, operational training, and ongoing support.

If your machine experiences a malfunction, you should first contact our technical support team for assistance. We offer remote troubleshooting services and, if necessary, can send technicians for on-site repairs.

Yes, we offer regular maintenance services to ensure the longevity and optimal performance of your machine. Our maintenance packages can be customized based on your usage needs.

We offer a warranty that typically covers key components such as the laser source, control system, and motors. The warranty period is generally two years, depending on the product. Extended warranties and service packages are also available.

The price of a fiber laser cutter varies based on factors such as power, size, and additional features. Machines typically range from $30,000 to over $200,000 depending on the configuration.

We accept a variety of payment methods, including bank transfers (T/T), letters of credit (L/C), and other methods like leasing or financing options, depending on your location and specific needs.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.