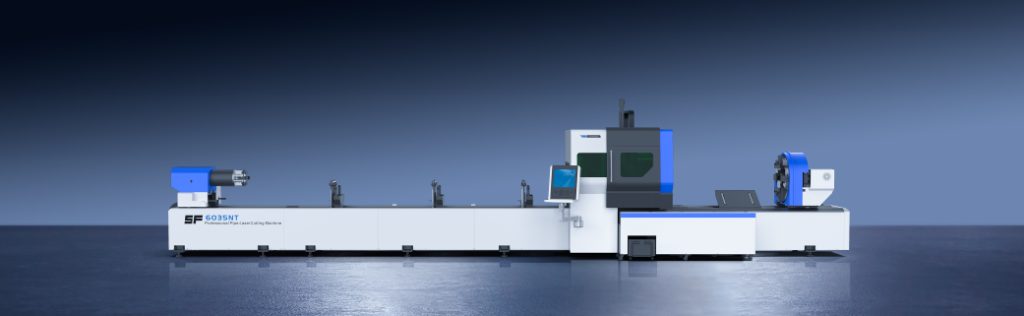

This all-purpose machine fits for cutting long (6000-12000mm) and large (360mm at most) tube. There are three chucks, though, but 0 tailing is also possible to achieve as long as related procedures are well-arranged. It is good for maximizing materials and saving costs of purchase.

1.5-6 [kW] Laser power

6000-12000 [mm] Max length of tube

20-360 [mm] Tube size

250-1000 [kg] Max weight of tube

| Main Parameters | Model | ||||

| SF6024NT | SF6035NT | SF9024NT | SF9035NT | SF12035NT | |

| Laser Power (kW) | 1.5-6 | 1.5-6 | 1.5-6 | 1.5-6 | 1.5-6 |

| Max Length of Tube (mm) | 6000 | 6000 | 9000 | 9000 | 12000 |

| Scope of Tube Size (mm) | Φ20~240 □20*20~230*230 |

Φ20~360 □20*20~360*360 |

Φ20~240 □20*20~230*230 |

Φ20~360 □20*20~360*360 |

Φ50~360 □50*50~360*360 |

| Max Weight of Tube (kg) | 250 | 1000 | 250 | 1000 | 1000 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| Max No-load Speed (m/min) | 75 | 60 | 75 | 60 | 60 |

| Max Rotating Speed of Chucks (r/min) | 100 | 60 | 100 | 60 | 60 |

| Overall Dimensions (L*W*H, mm) | 13350*2750*2615 | 13500*2750*3390 | 16500*2750*2615 | 16500*2750*3390 | 19500*2750*3390 |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | ||||

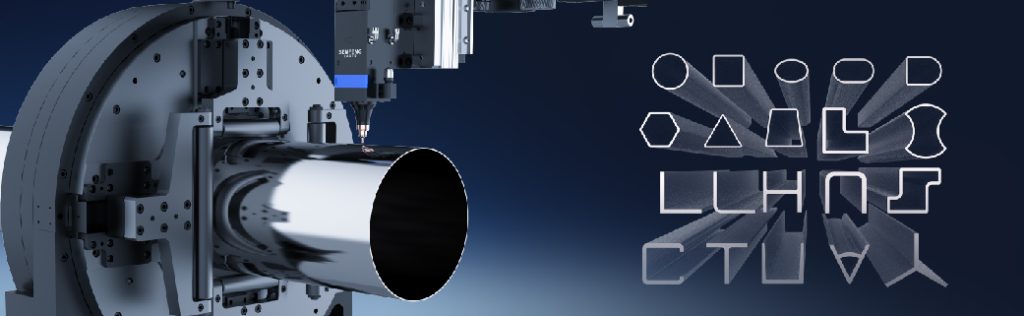

It is used to cut round, square, rectangular, oval tube, I-beam, as well as channel, angle tube, C-profile and H-shaped steel at high precision.

⇲ Special for cutting long tube

Tube length: 6000-12000mm

Round tube: Φ20~360mm, square tube: □20*20~360*360mm, rectangular tube: (side length)

⇲ Multiply cutting speed

Roughly 70% faster than other similar models

⇲ Ease of operation

High degree of automation, much less manual intervention and consequent misoperation

⇲ Tried-and-tested design

Semi-enclosed structure at high level of integration

Three square-hole chucks to expand its clamping range

All-optical cutting head with autofocus and auto obstacle avoidance

Horizontal machine tool, featuring heavy loads, modular structure and coaxial treatment

Follow-up support available to protect cutting precision from tube sagging

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high positioning accuracy (±0.03mm)

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

The bus-based CNC system, with simple interface, is easy to operate and learn because of its high degree of intelligence. It can also support files in igs, sat, jhb and other formats.

⇲ Automatic nesting

Raise tube utilization rate and save raw materials to the utmost

⇲ 7-axis pulling

Innovative craft for dynamic cutting with 0 tailing

⇲ Real-time deviation compensation

Lower demands on tube quality and raise piercing precision sharply

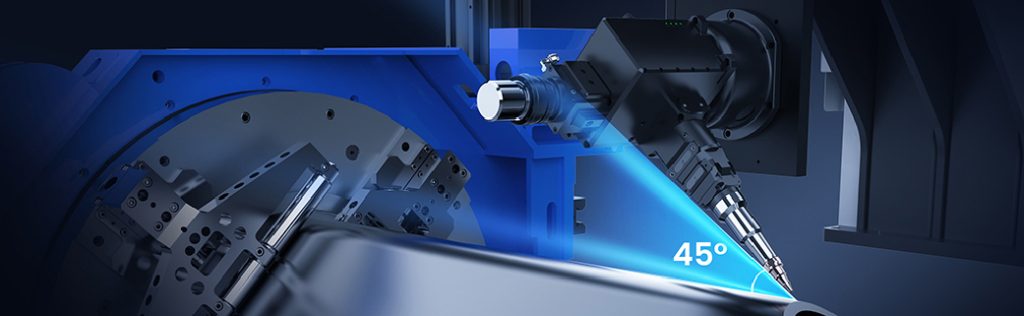

⇲ Bevel cutting (optional)

Cut tubes into ±45°bevel for easy subsequent welding

⇲ Innovative loading device

It comes standard with turnover plate to unload 2000mm long tube. But, users may apply for other fully-/semi-automatic loading & unloading devices as optional accessories. Basically no manual operation.

Fiber laser cutting machines work by directing a high-power laser beam onto a material’s surface, which heats and melts the material. The laser beam is guided by a fiber optic cable, allowing it to cut with precision and speed. The process involves localized heating, causing the material to melt or vaporize in the targeted area, and high-pressure gas is used to blow away the molten material, resulting in a clean cut.

Fiber laser cutting machines are highly versatile and can cut a wide range of materials, including:

⇲ Metals: Stainless steel, carbon steel, aluminum, copper, brass, and titanium.

The cutting thickness depends on the power of the laser. Generally:

⇲ For low-power machines (1kW-3kW), cutting thickness ranges from 1mm to 16mm for steel.

⇲ For high-power machines (above 3kW), cutting thickness can go up to 200mm for metals like steel, and thinner for reflective materials like aluminum or copper.

Yes, we provide comprehensive training and technical support to ensure that our customers are fully equipped to operate the machines. This includes installation guidance, operational training, and ongoing support.

If your machine experiences a malfunction, you should first contact our technical support team for assistance. We offer remote troubleshooting services and, if necessary, can send technicians for on-site repairs.

Yes, we offer regular maintenance services to ensure the longevity and optimal performance of your machine. Our maintenance packages can be customized based on your usage needs.

We offer a warranty that typically covers key components such as the laser source, control system, and motors. The warranty period is generally two years, depending on the product. Extended warranties and service packages are also available.

The price of a fiber laser cutter varies based on factors such as power, size, and additional features. Machines typically range from $30,000 to over $200,000 depending on the configuration.

We accept a variety of payment methods, including bank transfers (T/T), letters of credit (L/C), and other methods like leasing or financing options, depending on your location and specific needs.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.