What is Fiber Laser Cutting Machine

Fiber laser cutting machine is a kind of equipment using laser to cut materials. To be specific, laser generator outputs high-density laser beam that passes on to laser cutting head via optical fiber and gathers on workpiece through focusing lens, as a result, the materials are heated to melt down or gasify.

Ⅰ.How Does It Work

When fiber laser cutting machine is at work, its laser beam will focus into a tiny laser spot (≤0.1mm at minimum) where power density is very high, at this moment, the materials under laser spot are heated to gasification temperature to form an opening or hole. To keep moving along with the materials, the machine continues to pierce to connect these openings or holes together, causing a narrow gap. At this moment, laser cutting is over.

Ⅱ.Technical Features

1.Good cutting quality

Thanks to small laser spot and high energy density, it will be of good quality only after one-time cutting. In general, laser cutting gap is 0.1-0.2mm. There is narrow heat affected zone, well-cut gaps and regular cross section in rectangular shape. With no burr, the surface roughness after laser cutting can reach up to 12.5um or above. As the last step, laser cutting's section can be welded directly with no need for rework, and spare parts are allowed to be put into use directly.

2.Fast cutting speed

Considering that laser cutting has small heat affected zone, tiny deformation and no clamping fixation, it is good for saving both clamping fixtures and operating time.

3.Materials available in variety

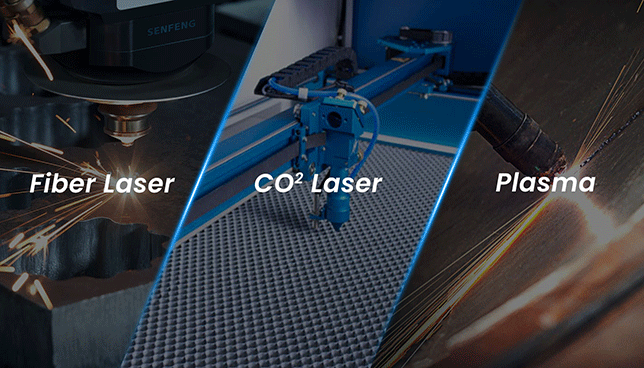

In comparison with plasma and other cutting methods, laser cutting can accept much more materials like metals, nonmetals, metal matrix and non-metallic matrix composites. Different materials usually show different adaptation to laser because of their difference in thermophysical characteristics and laser absorptivity.

4.Fit for large workpiece

Generally speaking, large workpiece needs high investment in mold manufacturing. However, laser cutting can do without any mold and prevent turned-down edges during punching. In this way, users can not only reduce production costs, but also upgrade their product quality.

5.Clean, safe and pollution-free

There are low noise, small vibration and no pollution during cutting, hence, workers will enjoy quality-improving workplace.

6.Free from electromagnetic interference

Unlike electron beam, laser is insensitive to electromagnetic interference and vacuum ambience is not required.

Laser cutting has emerged as an important way in sheet metal working industry and been favored by a host of manufacturers because of its increasingly more strengths. That is why fiber laser cutting machine is widely applied in metalworking, electronic, auto manufacturing, aerospace and so on.

Ⅲ.How to Choose Your Right Machine

In spite of increasingly wider application as laser cutting technology is developing, global market of fiber laser cutting machine is quite a mixed bag. This makes the choosing of an appropriate machine a big issue. Our advise is as follows:

First, actual demands

At present, there are three kinds of fiber laser cutting machines available on the market, namely, sheet laser cutting machine, tube laser cutting machine and sheet & tube laser cutting machine. All potential purchasers must make decision based on their specific metal types.

Second, laser power

We should break the inherent thinking that the higher laser power, the better the cutting effects. When purchasing, remember what fits is the best.

Third, cutting crafts and machine configuration

Sometimes, selling price is placed in preference to machine configuration. For fiber laser cutting machine, these core components are critical to laser cutting quality, including laser cutting head, laser generator, electric motor, machine tool, CNC system, protective or collimating lens. Don't overlook machine configuration on the pretext of selling price.

Finally, company brand

As a rule, large-sized enterprises with good brand are equipped with relatively complete R&D teams, technical supports and after-sales service. So, manufacturers that see good brand, high reputation and market share shall be on your shopping list in addition to conformance to your actual demands and stable performance.