6 Reasons to Choose a 12kW Fiber Laser or Above

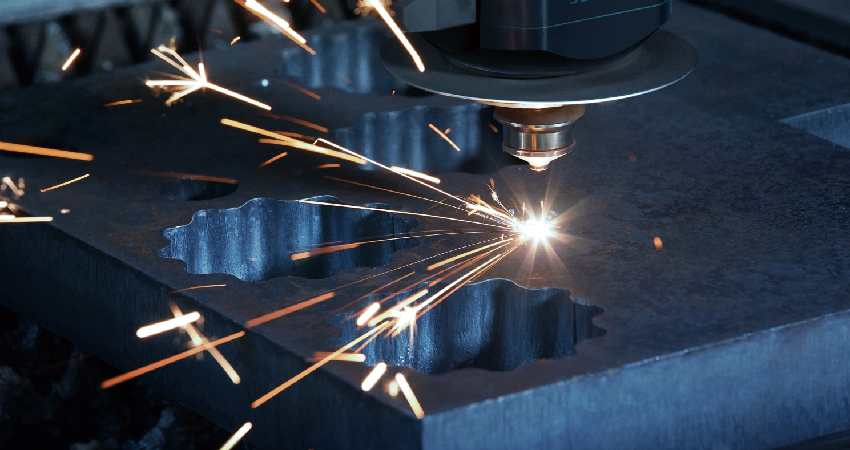

The history of laser cutting machines dates back to the 1960s, when the first artificial laser beam was created at Hughes Laboratory. However, it wasn’t until the 1970s that industrialization began, with Western Electric in the United States developing and producing the first laser cutter. Fast forward to today, laser cutting technology has advanced significantly, with machines now capable of cutting materials up to 100mm thick and powering up to 12kW or above, offering enhanced precision, speed, and efficiency. So, why are more and more metal processing manufacturers choosing 12kW fiber laser or above (including 12kW fiber laser, 15kW fiber laser, 20kW fiber laser, 30kW fiber laser, 40kW fiber laser, 60kW fiber laser, 80kW fiber laser)? What are the advantages of high-power equipment compared to medium and low-power machines?

1. Faster Cutting Speeds with a 12kW Fiber Laser

One of the most immediate advantages of a 12kW or above fiber laser cutting machine is its ability to cut at significantly faster speeds than lower-powered lasers. For example, when cutting 10mm carbon steel, a 6kW machine has a cutting speed of 1.8-2.3m/min, while a 12kW laser cutter can achieve speeds of 5-6.5m/min, nearly doubling the speed. This difference becomes even more apparent when cutting thinner materials. For instance, when cutting 3mm carbon steel, the 6kW machine cuts at a speed of 12-14m/min, whereas the 12kW laser cutter reaches speeds of 28-35m/min.

2. Ability to Cut Thicker Materials

As businesses demand versatility for diverse materials, a 12kW or higher laser cutter stands out. Higher power equates to higher energy density, enabling thicker material cutting. High-power machines feature sturdier beds, ideal for thick plates. While medium-to-low-power lasers cut up to 20mm steel, 12kW+ machines can handle materials up to 80mm thick.

For metal fabrication, construction, and shipbuilding, a 12kW+ fiber laser swiftly cuts thick materials with precision. Its capacity to handle large sheets without sacrificing speed or quality is vital for businesses expanding production.

3. Higher Cut Quality with a 12kW Fiber Laser

Another significant advantage of using a 12kW fiber laser cutter is the superior cut quality it provides. When cutting thicker materials, heat can often build up, causing warping, uneven edges, or dross. However, with a high-powered laser, the cutting process is far more efficient, and the results are much cleaner and more precise.

A 12kW fiber laser’s focused beam ensures sharp, smooth cuts on tough materials, vital in industries like automotive and electronics where precision matters. This tech boosts accuracy, cuts post-processing, and reduces scrap, leading to cost savings and better products.

4. Enhanced Cutting Precision with a 12kW Fiber Laser

High-power laser cutters offer significantly higher cutting precision. The increased power of the laser generates more intense heat, which results in finer cutting lines and smoother edges. This leads to an overall improvement in cutting quality.

Such enhanced precision is crucial for applications requiring high accuracy, such as aerospace components and precision mechanical parts. The ability to achieve such fine cuts ensures that demanding projects are completed with superior detail and minimal material wastage, making high-power lasers ideal for precision-driven industries.

5. Lower Maintenance Requirements

Another key benefit is the relatively low maintenance requirements compared to other cutting technologies. Fiber lasers have fewer moving parts and are less prone to wear and tear than traditional CO2 lasers, which means less downtime and lower maintenance costs. This is especially important for businesses looking to keep operational costs down and maximize the uptime of their machines.

Additionally, fiber lasers require less frequent servicing and do not need regular alignment adjustments, which are common with CO2 lasers. This reliability is an important factor for industries that rely on high-volume, continuous production, as it ensures consistent performance and reduces interruptions.

6. Improved Material Utilization

A 12kW fiber laser’s precision and speed also contribute to better material utilization. The ability to cut thicker materials efficiently means that businesses can use larger sheets of metal with fewer cuts, reducing waste. The advanced software used in conjunction with CNC fiber laser cutters also enables better nesting, maximizing the use of every square inch of material.

In industries such as aerospace and automotive manufacturing, where material costs can be high, reducing waste is crucial for maintaining profitability. By improving material efficiency, businesses can significantly lower their costs and increase their return on investment.

Conclusion: A Smart Investment for the Future

In conclusion, choosing a laser cutter with 12kW or more power offers numerous benefits that can significantly enhance the productivity, efficiency, and cost-effectiveness of metal laser cutting operations. These machines provide faster cutting speeds, the capability to cut thicker materials, superior cut quality, improved precision, and better energy and gas efficiency, making them an excellent choice for businesses aiming to remain competitive in an increasingly demanding market.

At SENFENG, we offer a range of high-power laser cutting machines (including 12kW, 15kW, 20kW, 30kW, 40kW, 60kW, and 80kW fiber lasers) tailored to meet the needs of modern manufacturers. Contact us today to learn how our advanced laser-cutting solutions can help elevate your business to the next level.