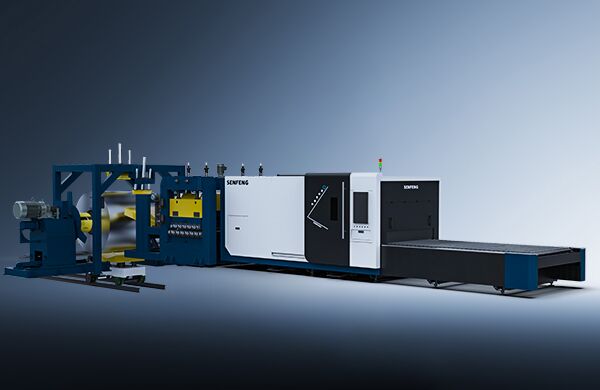

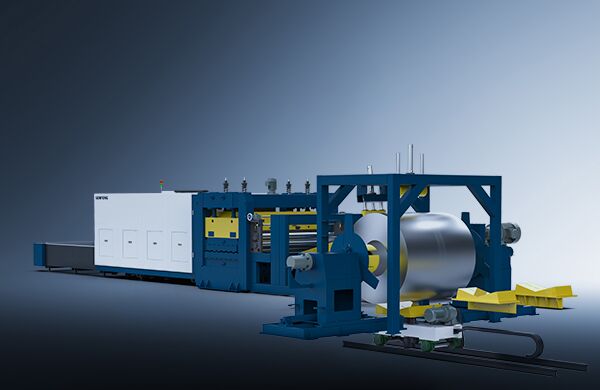

Coil Laser Blanking Line For 8-14mm Steel

This blanking line adopts high power and large working area to cut thick and heavy sheet coils. Combining decoiling, leveling, feeding and cutting together, this machine has developed into a one-stop production line from mere cutting.

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

Technical Parameters

| Main Parameters | Model | |

| SF2012CH | ||

| Decoiling and Leveling Unit | Size of Sheet Coil (L*W, mm) | 4000*2000 |

| Thickness of Sheet Coil (mm) | 8-14 | |

| Standard inner diameter of sheet coil (mm) | Φ610/Φ762 | |

| Max outer diameter of sheet coil (mm) | Φ1000-1800 | |

| Weight of Sheet Coil (T) | 20 | |

| Max Feeding Speed (m/min) | 10 | |

| Leveling Accuracy (mm/m²) | ±5 | |

| Laser Cutting Machine | Laser Power (kW) | 6 |

| X/Y-axis Positioning Accuracy (mm/m) | ±0.05 | |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | |

Videos

Competitive Strengths

This model, unlike other ordinary blanking lines only cutting thin sheet coils, can handle with 14mm thick sheet coil at most. With less working procedures, it is complementary to those models, so as to make our product line perfect

⇲ Special for large, thick and heavy sheet coils

* Max size of sheet coil: 4000*2000mm, inner diameter: Φ610/762mm, outer diameter: Φ1000-1800mm, thickness of sheet coil: 8-14mm, weight of sheet coil: 20T

* Its double-headed decoiler, hydraulic loading trolley, 11-roller leveling device and laser cutting machine with large working area work together to insure fast speed and high quality while cutting such special sheet coils

* Deal with carbon steel, AL alloy, brass, red copper, galvanized sheet, silicon steel sheet, electrolytic plate, titanium alloy, etc.

⇲ Cutting-edge processes

* Content-rich process package for lightning-fast cutting with mirror-like surface

* Utilize our patented rapid stress relief technology, which not only levels the sheet but also relieves internal stress, making the sheet flatter

* With ultra-high-precision positioning correction technology, its guide rollers are asked to correct sheets in real time, so as to avoid any offset and enable accurate positioning & high cutting precision

⇲ Need less costs of purchase

* Compared with punching and other traditional laser cutting modes, it can raise its material utilization by 5-10%

* We offer automatic auxiliary gas distribution device, so its control software may select gas type and pressure automatically to make manual operation unnecessary and save relevant costs

* With this machine, users prefer sheet coils to cut-to-length steel plates, enabling flexible clipping and much less costs of purchase because of their large price spread

⇲ Fully-enclosed structure

Laser cutting machine, with top cover, is designed as fully-enclosed to separate cutting area and prevent smoke dust from diffusion. Workers in the workshop will be in good health

⇲ Automatic assembly line

This assembly line is fully automatic, with no manual intervention from automatic loading, decoiling, leveling, feeding, cutting to unloading device. 30% faster than before at least and realize 0 waste as much as possible

⇲ International famous components

* Heavy-duty decoiling, feeding and leveling unit with steady structure and high carrying capacity

* New fiber laser generator outfitted with anti-reflectivity protection and high electro-optical conversion rate

* Fully-enclosed laser cutting head can prevent dust pollution effectively

* The cutting unit uses multiple sets of AC servo motors for faster response and more accurate control

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Protect both man and machine

* There are more than one set of safety monitoring systems. Its whole process is clear at a glance. If abnormal, alarm will be given in time to prevent unforeseen shutdown

* Adopt protective measures to avoid misoperation and users may cut off the power at full speed in case of emergency

* Electrical system has high capacity of resisting disturbance and automatic diagnosis to find the cause of failure quickly

Our self-developed intelligent system can correlate technical parameters to sheet coil (such as thickness) in its database, so that this production line may adapt to material change quickly and make its control fully digital and automatic.

⇲ Follow-up control

Adjust follow-up height from cutting head to sheet automatically to eliminate the impact on cutting effects of uneven sheets

⇲ Lightning-fast piercing

Pierce at top speed and enhance efficiency especially when cutting thin sheet

⇲ Recut from break point

Remember the cutting position after power outage, start recut from break point once power recover, thus avoiding material waste

⇲ Ink jetting system

Generate labels in batch and make inkjet printing more precise and eco-friendly

⇲ Safety grating

Protect both man and machine by warding off accidents

⇲ Self-developed nesting software

Nest and typeset in full volume to maximize material utilization

FAQ

What kind of company is SENFENG?

SENFENG is a group company that gives consideration to technical R&D, production, global sales and trading. Currently, it has established 3 major manufacturing bases in China, covering an area of over 180,000m2, with an annual output of tens of thousands of units. Additionally, it has set up local sales service agencies in the USA, Germany, UAE, Pakistan, India, Vietnam and Jordan, selling its machines to 100+ countries and regions.

What products and services does SENFENG offer?

SENFENG can research, produce and sell laser cutter (both sheet and tube cutting), press brake (incl. panel bender), welding machines, cleaning machines, cladding machines, various automation equipment, machine tools and new energy battery assembly lines. It has the most complete product line among peers, providing global users with metal forming automation solutions and achieving one-stop processing from raw materials to finished products.

Does SENFENG accept customization?

Yes, users can apply for customization of machine color, logo, overall dimensions and main configurations according to their preferences and actual needs, such as, core components like laser generator, cutting head, control system, water chiller, speed reducer and electrical system of different brands and functions. We will provide personalized solutions for global users within feasible limits.

What modes of payment are available?

At present, SENFENG supports T/T, L/C, Alipay, etc. We respect the customer’s right to choose their most fitting payment mode and will do our best to keep their funds safe.

Does SENFENG provide technical support and after-sales service?

Yes, SENFENG offers pre-sales, in-sales and after-sales services to global users both online and offline.

On one hand, hundreds of overseas customer service agents are available online 24/7 to answer various inquiries, including product consultation, customized solutions, complaints, etc., and we have established an online knowledge center providing a one-stop knowledge database.

On the other hand, sales engineers, technical engineers and after-sales engineers frequently visit customer sites for face-to-face communication to settle user’s troubles back at home.

More importantly, we also provide free online and offline operational training, such as theoretical & practical training, common fault self-diagnosis training and quick repair guidance for difficult faults, enabling all users even beginners to get started quickly.

How can I get a quote or more information?

Firstly, machine pricing depends on its laser power and technical configurations, so please leave a message with your specific requirements. Then, a sales engineer will recommend a suitable model for you before providing a quote.

Secondly, if you want to learn more about our company or products, you can browse this website in detail, contact us through WeChat official account, Facebook, YouTube, Twitter, Instagram, WhatsApp, etc., or request our internal promotional materials from a sales engineer, visit our overseas service centers nearby directly.

What is laser cutter and how does it work?

A laser cutter uses laser as heat source and can be classified as sheet cutting and tube cutting. This includes sheet laser cutter, tube laser cutter and sheet & tube combo, making it one of the most advanced metal processing equipment available today.

The laser cutter utilizes the high-density laser beam to convert laser energy into thermal energy, causing localized heating, melting or even vaporization of materials. The melted or vaporized material is then blown away by using gas flow or other methods to achieve cutting.

What materials are suitable for cutting with a laser cutter?

Laser cutter can cut a wide range of materials, incl. stainless steel, carbon steel, alloy steel, silicon steel, aluminum, aluminum alloy, galvanized sheet, aluminum-zinc plate, pickled sheet, titanium, and other metal sheets.

They can be applied in most metalworking industries, such as sheet metal working, kitchenware, aerospace, electrical cabinet, household kitchenware, automotive parts, construction and agricultural machinery, and more.

How should a customer choose a laser cutter that exactly meets his needs?

When selecting a laser cutter, we believe users should focus on 10 factors below:

* Laser power * Cutting speed * Cutting accuracy * Type of laser generator

* Degree of automation and software * Ownership costs * Material compatibility

* Technical support and service * Installation space and requirements * Environmental and safety factors

What should you pay attention to while maintaining a laser cutter?

Laser cutter can cut a wide range of materials, incl. stainless steel, carbon steel, alloy steel, silicon steel, aluminum, aluminum alloy, galvanized sheet, aluminum-zinc plate, pickled sheet, titanium, and other metal sheets.

They can be applied in most metalworking industries, such as sheet metal working, kitchenware, aerospace, electrical cabinet, household kitchenware, automotive parts, construction and agricultural machinery, and more.

What advantages does a laser cutter have compared to other traditional cutting modes?

Laser cutting replaces traditional mechanical blades with an invisible beam of laser, offering high precision, fast cutting, no limitation on cutting patterns, automatic nesting to save materials, smooth cut edges and low operating costs. It is gradually improving or replacing traditional metal cutting processes.

* The mechanical parts of laser cutting head don’t contact workpiece, preventing surface scratches during operation.

* Laser cutting is fast, with smooth and flat edges that typically require no further processing.

* The heat-affected zone is small, resulting in minimal deformation of sheet and narrow cutting seams (0.1-0.3mm).

* Cuts have no mechanical stress nor shear burrs.

* High cutting precision and good repeatability without damaging the material surface.

* CNC programming allows for the processing of any flat pattern and the cutting of large entire sheet without the need for molds, saving both time and costs.

What is the warranty period of laser cutter?

The complete machine is under 2-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.

Does laser tube cutting machine have auto-correction function?

Yes. Our machines are usually equipped with advanced CNC systems that use capacitance centering to measure tube’s actual size and automatically calibrate to align the tube profile with its model. It also features real-time compensation for tube deviation, reducing requirements for tube clamping and improving the tube piercing accuracy.

What is press brake and how does it work?

A press brake is a device that can bend thin sheet metals. It generates pressure through a hydraulic system, which is transmitted by upper and lower molds to achieve the desired bending shape. Depending on its drive mode, level of automation and structure, press brakes can be classified into manual, hydraulic and CNC press brakes.

What is panel bender and how does it work?

Panel bender is a highly automated bending machine, representing the latest advancement in sheet metal bending. It can bend into various complex shapes such as right angle, arc, up and down, without the need for manual holding of workpiece or bending mold. One-time positioning is enough for multi-side bending. Its bending speed is about 3 times faster than traditional press brakes. Due to the fewest human intervention, the consistency among workpieces is much higher, and it is gradually replacing the tradition.

For the panel bender, workers only need to place workpieces on its worktable, then, the workpiece will be positioned by suction cup or press-down arm and bent automatically. A set of universal bending mold is enough, without frequent change or customization.

What is bending ability of a press brake?

A press brake is a type of forging machinery primarily used for sheet metal processing, especially for large sheets. By adopting different molds, it can perform operations such as bending edges, stretching, rounding and punching on the sheet metal.

What should a novice pay attention to when using press brake for the first time?

Operating press brake is not only a challenge but also a chance to grow up for beginners. By following tips below, they can navigate the complexities of CNC press brake operation with greater ease and efficiency.

* Familiar with the press brake and operating manual

* Receive professional training

* Set and adjust parameters correctly

* Gradually master programming skills

* Focus on material selection

* Adhere to safety operating procedures

* Monitor and adjust machine status

* Perform regular maintenance

* Accumulate practical experience

What is the warranty period of press brake?

The complete machine is under 1-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.

What is laser welding machine and how does it work?

A laser welding machine is a device used for welding materials. It has a high power density and fast energy release, making its welding efficiency superior to other traditional welding patterns. Whether welding the same type or different materials, it is unnecessary to carry out secondary treatment. Its emergence has led to a large leap in welding technology.

Laser welding utilizes high-energy laser beam to locally heat small areas of materials. The energy from laser radiation quickly diffuses into the material through thermal conduction, melting the material to form a specific molten pool for welding purpose.

What kinds of welding machines can SENFENG produce?

Currently, SENFENG can offer more than 10 kinds of different welding machines for customers worldwide. According to degree of automation, we have handheld and robot-assisted machines. Based on cooling mode, there are air-cooled and water-cooled types. With regard to heat source, laser welding and electric-arc welding are available now. Customers may make decision or apply for customization as needed.

What types of welding can laser welding achieve?

Main welding types include butt welding, overlay welding, stitch welding, stud welding, T-joint welding, internal & external corner welding and seal welding. It has advantages such as deep welding depth, narrow width, small heat-affected zone, minimal deformation and fast welding speed.

What are the main applications of laser welding?

Laser welding uses laser beam as heat source. The main objects of welding are thin-walled materials and precision parts, such as stainless steel, carbon steel, mold steel, copper, aluminum, gold and silver. It can also repair defects such as wear, pore, sand hole, crack, scratch, deformation, and reduced hardness in workpieces.

What is the warranty period of laser welding machine?

The complete machine is under 1-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.

What is laser cladding and how does it work?

Laser cladding is an important method for surface modification of materials. It uses high-energy laser beam to irradiate the metal surface for rapidly melting, expanding and solidifying. The cooling rate typically reaches 102 to 106℃/s, then, a layer of material with special physical, chemical or mechanical properties will take its shape on the substrate surface, thus creating a new composite material. This process can compensate for the lack of high performance in the base material and significantly improve substrate surface properties in terms of wear, corrosion, high temperature and oxidation resistance.

What are technical characteristics of laser cladding?

Compared to commonly used methods such as overlay welding, thermal spraying and plasma spraying, laser cladding has the following advantages:

* The heat-affected zone is small, resulting in minimal deformation of workpiece and a high yield of cladding.

* The layer has fine crystal grains and dense structure, leading to relatively high hardness and better wear and corrosion resistance.

* Due to short duration of laser action, the dilution rate of cladding layer is low, which causes a smaller amount of material melted (typically 5%-8%). Therefore, it is possible to achieve the desired composition and properties even with a thin cladding layer, and to produce new structural features such as metastable phase, ultra-dispersed phase and amorphous phase.

* It is easy to automate the laser cladding, and the quality of cladding layer is always stable.

What materials are typically used for laser cladding?

The materials used for laser cladding are mainly thermal spraying and thermal welding materials, such as self-fusing alloy materials, carbide dispersion, or composite ceramic materials, which possess excellent wear and corrosion resistance. They are usually used in powder form, and during cladding, flames spray-welding may be employed to achieve a smooth surface with good adhesion to the substrate.

What is the warranty period of laser cladding machine?

The complete machine is under 1-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.

What is CNC Milling Machine?

It is an equipment that uses digital information control to carry out milling. It has characteristics of high precision, high efficiency and high automation, and develops into an indispensable equipment in modern manufacturing industry.

What are the main advantages of CNC Milling Machine?

Compared to other common machine tools, it is featured by:

* High processing accuracy with stable quality.

* Capable of multi-coordinate linkage, allowing for the cutting of complex-shaped parts.

* When changing spare parts, only CNC program needs to be modified, saving make-ready time for production.

* The machine tool itself has high precision and rigidity, resulting in high productivity (typically 3-5 times that of others).

* High degree of automation, which can reduce labor intensity.

* Higher quality requirements for operators and even higher technical requirements for maintenance staff.

What are main applications of CNC Milling Machine?

Currently, it has been widely used in machinery manufacturing industry and can deal with shaft, disc and sleeve-shaped parts. For example, CNC Milling Machines is extensively used for processing components like engine blocks, cylinder heads and crankshafts in automotive manufacturing industry. As for aerospace field where spare parts are under high precision requirements, CNC machine tool can also meet the demands for high-precision machining.

What is the warranty period of CNC Milling Machine?

The complete machine is under 1-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.