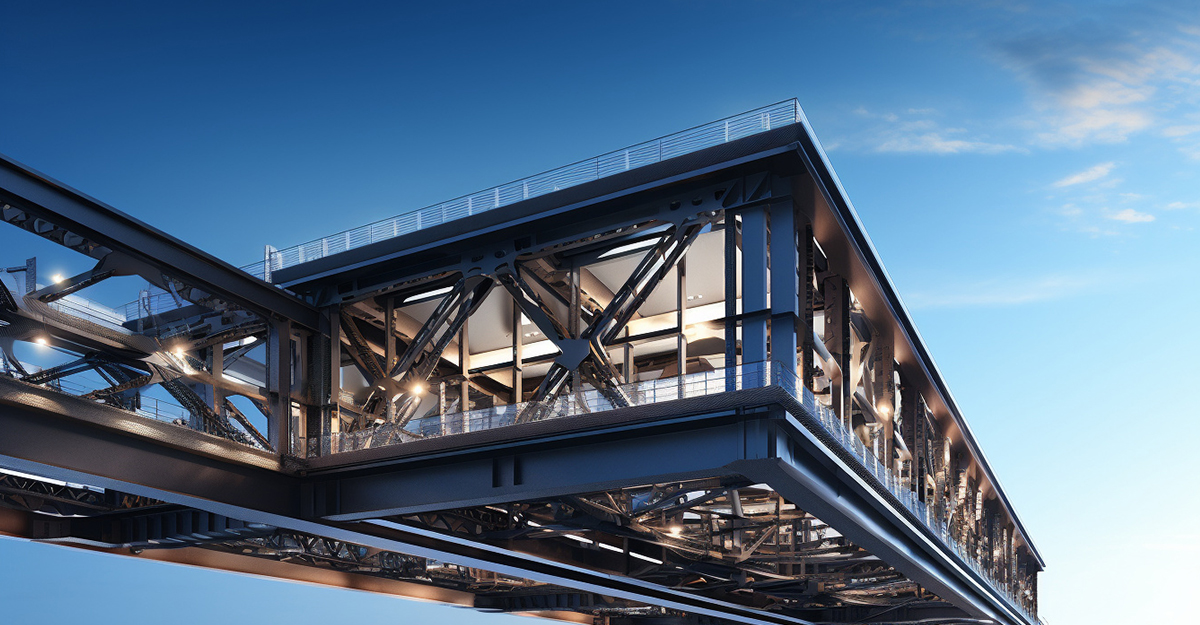

⇲ Achieve green building

⇲ Make high-rise building safer

⇲ Allow for large-span structures

⇲ Push forward urbanization and infrastructure construction

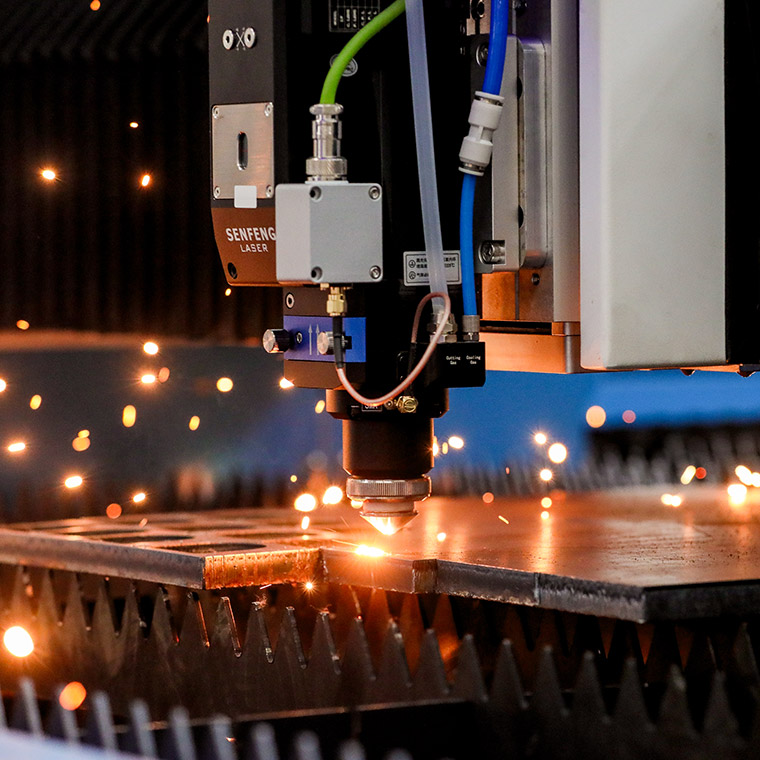

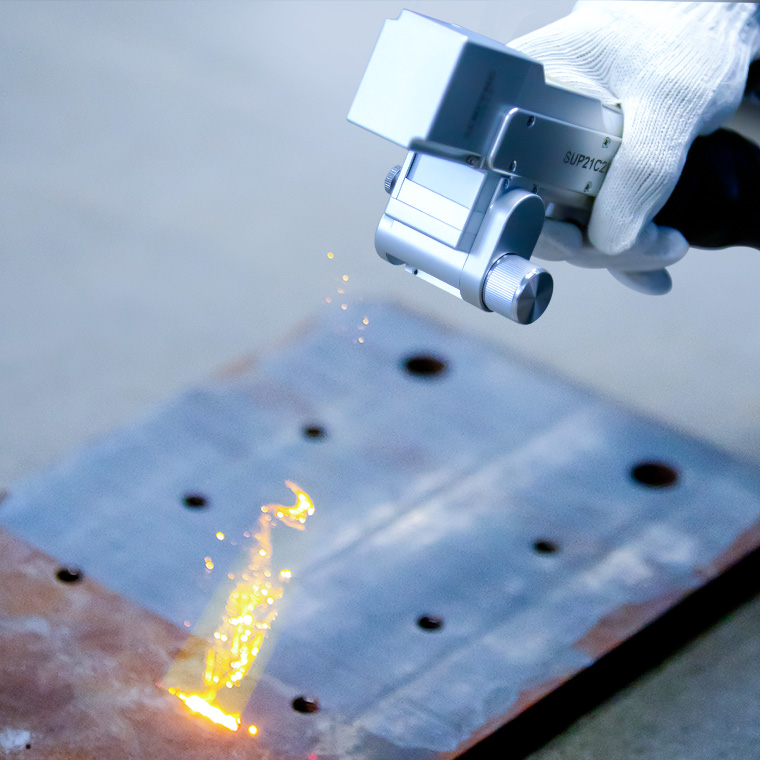

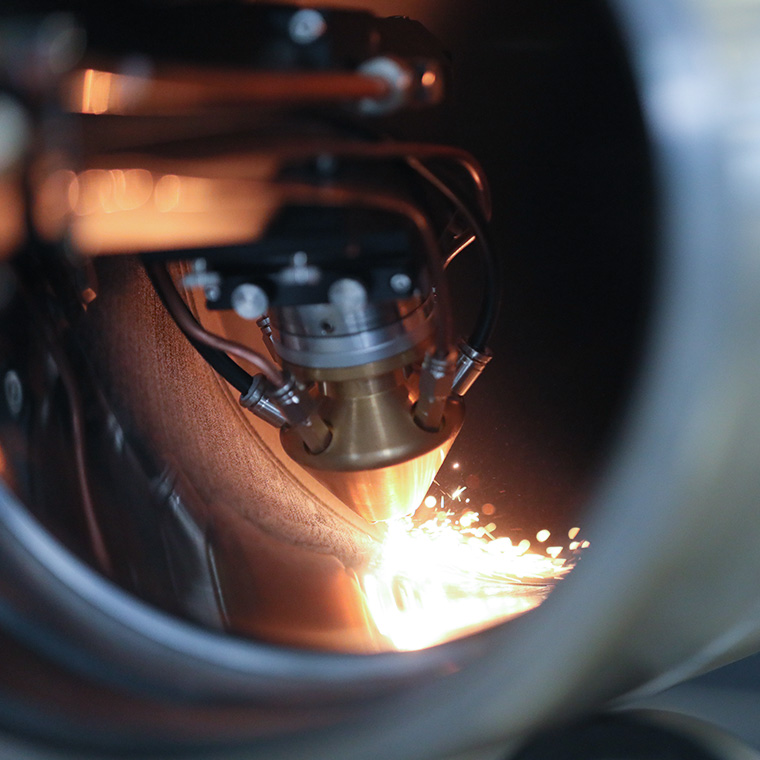

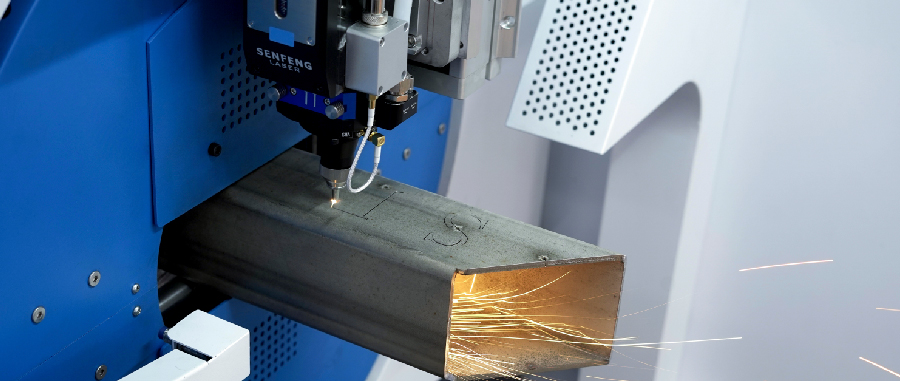

In general, steel structure involves various machining crafts. With fast development and widespread use of laser, traditional metalworking is gradually replaced or supplemented by laser technology. Currently, the following crafts are mainly used in steel structure field.

As a global provider in metal forming solutions, SENFENG has rich experience in metalworking, with its machines and technologies successfully applied in various stages of automobile production.

In Feb. 2024, a large state-owned construction company needed to buy new equipment due to undertaking a national-level project. This project had high demands on technology and precision, which are exactly our superiority. After nearly two months of market survey and comparison, they ultimately bought a laser tube cutter and a cladding machine from us, which were successfully delivered in May.

⇲ Time of purchase: Apr. 2024

⇲ Specific models:

12m Laser Tube Cutter with Three Chucks 12035NT

Internal Wall Laser Cladding Machine SFC

Completely synergize resource taxing.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.