A high-power high-performing machine recently upgraded in 2024. Ranging from 6kW to 30kW, it is suit to cut medium-thick plate (≥20mm) and featured by fast speed and high precision. Needing much less working time and costs, it has developed into the first choice for users who pursue for high cutting efficiency.

6-30 [kW] Laser power

3080*1530-12550*2830 [mm] Plate size

180 [m/min] Max no-load speed

3000-16000 [kg] Load of platforms

| Main Parameters | Model | ||||||

| 3015H | 4020H | 6020H | 6025H | 8025H | 12025H | 12528H | |

| Laser Power (kW) | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 |

| Working Area (L*W, mm) | 3080*1530 | 4050*2030 | 6050*2030 | 6050*2530 | 8050*2530 | 12050*2530 | 12550* 2830 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| Max No-load Speed (m/min) | 180 | 180 | 180 | 180 | 180 | 169 | 180 |

| Max Load of Platforms (kg) | 3000 | 3200 | 4750 | 6000 | 8000 | 14000 | 16000 |

| Overall Dimensions (L*W*H, mm) | 8440*2270*2340 | 10876*3363*2515 | 14887*3363*2515 | 14740*3893*2515 | 19075*3893*2515 | 27927*3893*2515 | 28877*4233*2515 |

| Power Supply | Three-phase 380V, 50Hz/60Hz | ||||||

This machine works stably and has good dynamic performance, so as to serve users for a long time at ultra-high power.

⇲ Cut medium-thick plate

6-90mm stainless steel, 5-80mm carbon steel, 5-60mm AL alloy, 5-30mm brass

⇲ Multiply cutting speed

About 3-5 times faster than other plate laser cutters

⇲ High degree of intelligence

Top configurations in both software and hardware, in particular some unique functions, so its oversea market reception is rising steadily

⇲ Tried-and-tested design

Double exchange platforms available to save waiting time for loading & unloading

Adopt hollow machine tool and graphite plates as fire prevention

Aviation-grade AL beam at high strength, enabling its cutting into various shapes at high speed

Fully-enclosed structure, with flip-in air door and dust curtain for safety and environmental protection

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (2.8G) and positioning accuracy (±0.05mm).

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

This professional CNC system is internally installed with many functions to easily cut plates at different thicknesses in different work conditions.

⇲ Lightning-fast piercing

Fast to pierce through thick plates at high quality

⇲ Visual detection of residues

Further use of residues to minimize plate waste

⇲ Visual collision avoidance

All-round monitoring without dead zone, making cutting safer

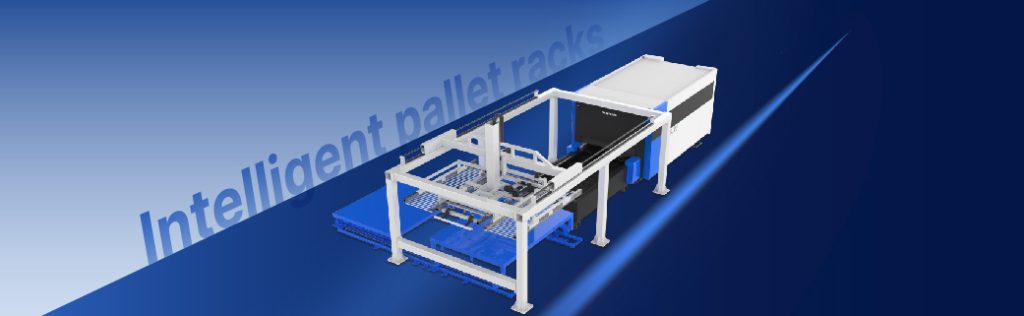

⇲ Intelligent pallet racks

Store, transfer, warehouse-in/out, load and unload plates automatically, making for efficiency gains and space utilization

Fiber laser cutting machines work by directing a high-power laser beam onto a material’s surface, which heats and melts the material. The laser beam is guided by a fiber optic cable, allowing it to cut with precision and speed. The process involves localized heating, causing the material to melt or vaporize in the targeted area, and high-pressure gas is used to blow away the molten material, resulting in a clean cut.

Fiber laser cutting machines are highly versatile and can cut a wide range of materials, including:

⇲ Metals: Stainless steel, carbon steel, aluminum, copper, brass, and titanium.

The cutting thickness depends on the power of the laser. Generally:

⇲ For low-power machines (1kW-3kW), cutting thickness ranges from 1mm to 16mm for steel.

⇲ For high-power machines (above 3kW), cutting thickness can go up to 200mm for metals like steel, and thinner for reflective materials like aluminum or copper.

Yes, we provide comprehensive training and technical support to ensure that our customers are fully equipped to operate the machines. This includes installation guidance, operational training, and ongoing support.

If your machine experiences a malfunction, you should first contact our technical support team for assistance. We offer remote troubleshooting services and, if necessary, can send technicians for on-site repairs.

Yes, we offer regular maintenance services to ensure the longevity and optimal performance of your machine. Our maintenance packages can be customized based on your usage needs.

We offer a warranty that typically covers key components such as the laser source, control system, and motors. The warranty period is generally two years, depending on the product. Extended warranties and service packages are also available.

The price of a fiber laser cutter varies based on factors such as power, size, and additional features. Machines typically range from $30,000 to over $200,000 depending on the configuration.

We accept a variety of payment methods, including bank transfers (T/T), letters of credit (L/C), and other methods like leasing or financing options, depending on your location and specific needs.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.