Vertical machining center, developing from CNC milling machine, can carry out vertical milling, drilling, boring, expanding, tapping and other procedures after one-time clamping of workpiece. It is used by SENFENG to set the global quality milling trend. With it, users can respond to the market instantly.

1000*550-1600*800 [mm] Worktable size

6000/8000 [r/min] Max speed of spindle

24 [cutter] Tool magazine capacity

2.5 [s] Tool changing time

| Main Parameters | Model | ||||||

| SF-VL855 | SF-VL1160 | SF-VL1160P | SF-VL1370 | SF-VL1580 | SF-VL1690 | ||

| Worktable | Dimensions (mm) | 1000*550 | 1200*600 | 1200*600 | 1400*700 | 1600*800 | 1600*800 |

| Max Load (kg) | 500 | 800 | 800 | 800 | 1500 | 1500 | |

| T-slot Size (mm) | 5-18-90 | 5-18-100 | 5-18-100 | 5-18-130 | 7-22-110 | 7-22-110 | |

| Processing Range | 3-axis Travel (mm) | 800*550*550 | 1100*600*600 | 1100*600*600 | 1300*700*750 | 1500*800*700 | 1600*900*700 |

| Distance from Spindle Nose to Table Surface (mm) | 120-670 | 120-720 | 120-720 | 120-870 | 160-860 | 150-850 | |

| Distance from Spindle Center to Z-axis Guideway Surface (mm) | 590 | 650 | 650 | 722 | 855 | 910 | |

| Spindle | Taper Hole (7:24) | BT40 Φ150 | BT40 Φ150 | BT40 Φ150 | BT40 Φ150 | BT50 Φ155 | BT50 Φ190 |

| Speed Range (r/min) | 8000 | 8000 | 8000 | 8000 | 6000 | 6000 | |

| Feed | 3-axis Rapid Speed (m/min) | 32/32/24 | 24/24/18 | 36/36/24 | 24/24/18 | 24/24/24 | 20/20/12 |

| Feed Speed (mm/min) | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | |

| Disc Tool hanger | Capacity | 24T | 24T | 24T | 24T | 24T | 24T |

| Tool Changing Time (s) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Positioning Accuracy | X/Y/Z-axis Positioning/Repositioning Accuracy (mm) | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 |

This machine adopts vertical spindle and high-rotating cutters to mill metals in order to remove something or drill into metal. It will create substantial economical benefits while dealing with spare parts of complex shapes and frequent variety changes but under high precision demands.

⇲ One machine with multiple functions

It can finish multi-face machining by only one-time clamping, such as drilling, tapping, reaming, milling and boring.

⇲ Superior in ability

Thanks to its standard face & end milling cutters, U-shaped drilling cutter and thread tapping cutter, the machine can mill flat surface, groove, profile, slope profile, deep hole and internal thread, in support of a wealth of milling demands.

⇲ Less labor error

Its whole milling process is under digital and automatic control. So, much less labor error becomes a booster of high work precision.

⇲ High degree of safety

Through 48h continuous work accessibility tests, the overall fault feedback rate is smaller than 1%, securing consistently reliable performance

⇲ Compact in structure

* The machine is compact in size. Its small footprint requires tiny working space

* With modular structure, it is easy to repair and replace faulty parts when needed

* Its full cover and front pulling door keep workers informed of work progress anytime

⇲ Hi-end tool magazine

The machine comes with 24T disc tool magazine and automatic tool changer (2.5s only each time) to keep the magazine stable

⇲ Machine tool at high strength

* The machine tool is featured by low vibration and high rigidity after going through rough machining, natural & secondary aging and finish machining; Its one-piece base, made of gray cast iron outperforms in load, capacity, rigidity and abrasion resistance

* Large-span humanoid column is internally outfitted with reinforcing bars to become more resistant to bending and torsion and work more stably at fast-speed milling

* The chrome-molybdenum alloy steel spindle has been subject to thermal treatment and precision grinding and equipped with air shaft seal

* 3-axis lead screw can make sure of high positioning and repositioning accuracy thanks to pre-stretching process

* The central forced lubricating pump is also employed to lubricate all moving parts in time

⇲ User-friendly design

* Its operating panel can rotate to the desired optimal angle at will for easy operation

* The maximally opened front pulling door facilitates both loading and unloading

* Inside the machine tool, the forward-tilting base tray works with flushing fluid and automatic shavings cleaner to remove shavings instantly. It can prevent machine body deformation caused by heat conduction

* Water-proof base tray and side window have undergone 48h continuous leak-proof tests

* High-volume water tank with multi-stage filtration will recycle milling liquids and save relevant costs

* Basket-type filter box helps to remove built-up shavings

FANUC CNC system reserves communication and USB interfaces to deal with workpieces of complex curved surface and profile at high speed and precision.

⇲ LCD color display screen

10.4-inch screen to showcase its rich preset functions

⇲ Graphic simulation

Graphically simulate the moving path of cutters

⇲ Automatic alarm

Record alarm time and details automatically, so that users will find out alarm causes instantly

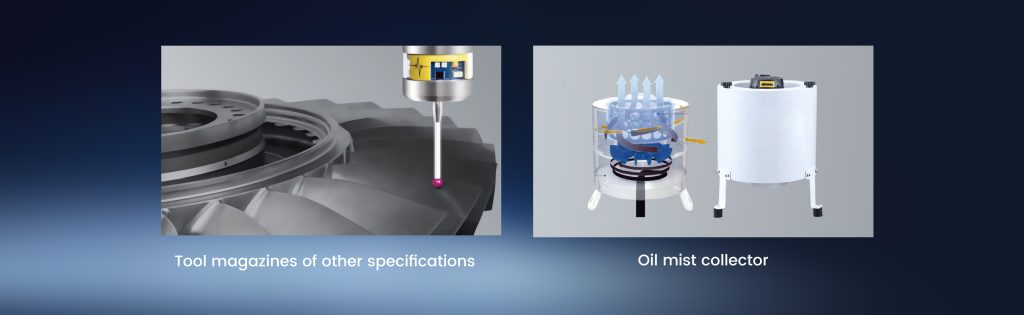

⇲ Tool magazines of other specifications

Other 30T tool magazines are also provided as optional accessories to offer cutters of different weights, lengths and outer diameters

⇲ Oil mist collector

Collect and purify oil mist, water mist and other hazardous substances at work, in this way, minimize workshop pollution and protect workers well

Fiber laser cutting machines work by directing a high-power laser beam onto a material’s surface, which heats and melts the material. The laser beam is guided by a fiber optic cable, allowing it to cut with precision and speed. The process involves localized heating, causing the material to melt or vaporize in the targeted area, and high-pressure gas is used to blow away the molten material, resulting in a clean cut.

Fiber laser cutting machines are highly versatile and can cut a wide range of materials, including:

⇲ Metals: Stainless steel, carbon steel, aluminum, copper, brass, and titanium.

The cutting thickness depends on the power of the laser. Generally:

⇲ For low-power machines (1kW-3kW), cutting thickness ranges from 1mm to 16mm for steel.

⇲ For high-power machines (above 3kW), cutting thickness can go up to 200mm for metals like steel, and thinner for reflective materials like aluminum or copper.

Yes, we provide comprehensive training and technical support to ensure that our customers are fully equipped to operate the machines. This includes installation guidance, operational training, and ongoing support.

If your machine experiences a malfunction, you should first contact our technical support team for assistance. We offer remote troubleshooting services and, if necessary, can send technicians for on-site repairs.

Yes, we offer regular maintenance services to ensure the longevity and optimal performance of your machine. Our maintenance packages can be customized based on your usage needs.

We offer a warranty that typically covers key components such as the laser source, control system, and motors. The warranty period is generally two years, depending on the product. Extended warranties and service packages are also available.

The price of a fiber laser cutter varies based on factors such as power, size, and additional features. Machines typically range from $30,000 to over $200,000 depending on the configuration.

We accept a variety of payment methods, including bank transfers (T/T), letters of credit (L/C), and other methods like leasing or financing options, depending on your location and specific needs.

We're here to help! Please fill out our inquiry form, and our team will respond promptly.